Multi Inject

Les trois modèles de robots Multi-Inject sont spécialement conçus pour le déchargement transversal des presses multi-injection avec une unité d’injection secondaire verticale A la différence du robot cartésien classique, ce robot cartésien 3 axes est conçu avec un bras de démoulage coulissant sur l’axe horizontal. Les robots Multi Inject 20 et 30 pour injection plastique permettent un accès vertical dans le moule. Ils sont plus économiques qu’un robot à accès latéral tout en bénéficiant de la flexibilité d’un robot 3 axes cartésien.

Télécharger la plaquettePrésentation

- Guidages prismatiques pour une grande rigidité

- Servomoteurs puissants et soft intelligent pour des temps d’intervention dans le moule réduit

- Implantation transversale ou portique au-dessus du moule

- Bras direct pour MI20 – Bras télescopique pour MI 30

- Armoire électrique sur poutre pour dégager l’espace ou au sol (option)

- Maintenance simplifiée – périodicité annuelle

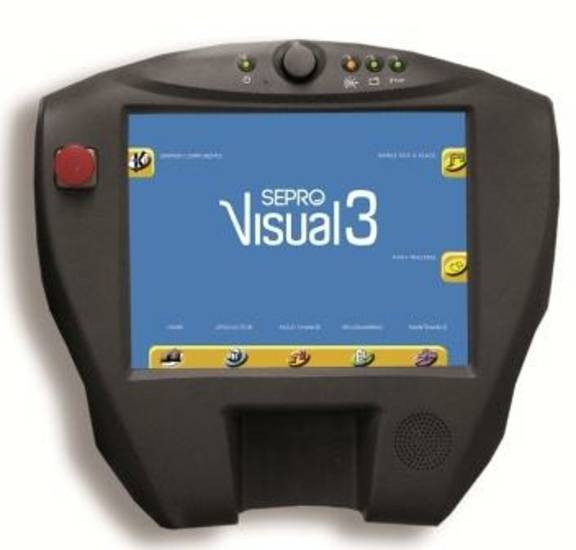

Systèmes de contrôle

Spécifications

Application

- Le déchargement transversal des presses multi-injection équipées d’une unité d’injection secondaire verticale

Vous pourriez être aussi intéressé par :

Premium 5X Line

Premium IML : In-Mold-Labelling system

Technology S7 Line

Contactez notre équipe commerciale

Tous les champs sont obligatoires

Comment pouvons-nous vous aider ?

Les informations collectées par SEPRO ROBOTIQUE font l'objet d'un traitement électronique afin de mettre en place des relations commerciales entre vous et le service commercial de SEPRO ROBOTIQUE. Les données collectées via ce formulaire sont obligatoires à l'exception de celles marquées comme facultatives. Le destinataire des données est le service commercial de SEPRO ROBOTIQUE, responsable du traitement. Vos données seront conservées pendant le temps nécessaire au traitement de vos demandes. Conformément à la loi Informatique et Libertés du 6 janvier 1978 modifiée et au RGPD, vous disposez d'un droit d'accès, d'interrogation, de limitation, de transfert, de modification, de rectification et d'effacement de vos données personnelles. Vous pouvez également vous opposer à tout moment au traitement de vos données personnelles. Vous pouvez exercer ces droits en nous adressant un e-mail à l'adresse suivante: dataprotection@sepro-group.com ou en écrivant à SEPRO ROBOTIQUE SAS, 88 rue Henry Bessemer, ZI Acti-Est, CS 10084, 85003 La Roche Sur Yon, France, en y adjoignant une copie de leur pièce d'identité signée.