Success The success of your applications

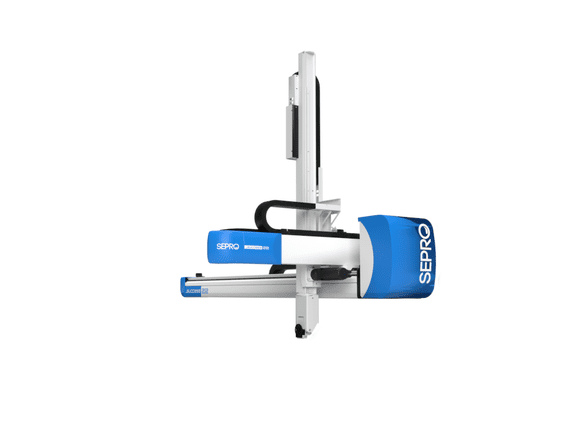

Success is a range of universal and economic robots that provide all the performance and reliability that you expect from Sepro.

The Success Line has been completely redisigned by Sepro. This best-seller is now also available in a 5-axis version, making best-in-class technology more affordable and more compact. These 3 or 5-axis are available for IMMs from 60 to 900 tons and enhanced gripping components : larger capacity & more compact.

Download the brochure

Presentation

«What you see is what you get»

Overview

- 3 & 5-axis

- New Cam for follower technology

- Up-to-date design

- More compact and increased rigity

- Enhanced Gripping components

- Optimized maintenance operations

- Higher payload capacity

- Wider strokes for more IMM size compatibility

Recognized reliability

Success is a range of universal robots that reinforces the fundamentals of the best seller, Axess, which has been sold in thousands, in particular with longer strokes and heavier loads. Like Axess, Success is equipped with the Touch 2 control system.

When reliability rhymes with innovation

Success benefits from the very latest technology, as well as the reliable and high-performance mechanical designs developed by our design offices. Success has been designed from the modular S mechanical platform developed for Success and S5 Line.

Simply Intuitive

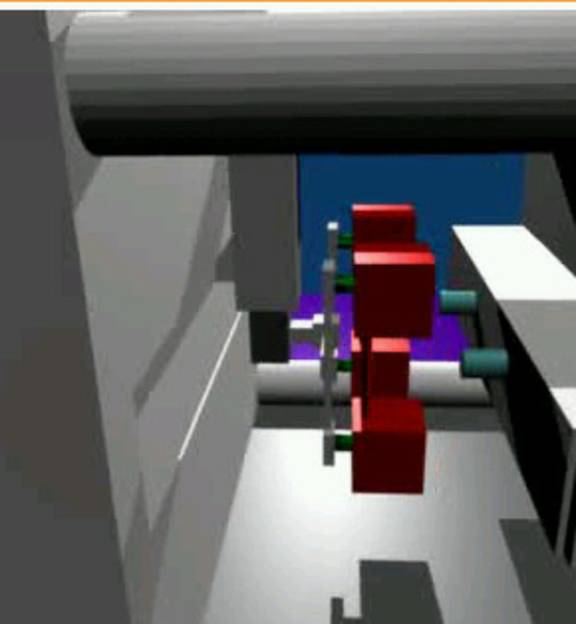

With the Simple Pick-and-Place Module, create your cycle by just answering the system’s questions and see the result immediately in 3D on the video (Simple Pick-and-Place and regular stacking).

Control systems

Specifications

Applications

- Simple Pick & Place

- Simple stacking applications

- Complex applications with Visual 2

About Success

You may also be interested in:

Premium 5X Line

Technology S5 Line

Premium 6X Visual: Sepro - Yaskawa

Contact our sales team

All fields are required

How can we help you?

The information collected by SEPRO ROBOTIQUE is processed electronically in order to set up commercial relations between you and SEPRO ROBOTIQUE's Sales Department. Data points collected via this form are required except those marked as optional. Data recipient is SEPRO ROBOTIQUE's Sales Department, the data controller. Your data will be kept for the time necessary to process your requests. Pursuant to the French Data Protection Act of 6 January 1978, as amended, and the GDPR, you have the right to access, query, limit, transfer, modify, correct, and erase your personal data. You may also object at any time to the processing of your personal data. You can exercise these rights by sending us an e-mail to the following address: dataprotection@sepro-group.com or by writing to SEPRO ROBOTIQUE SAS, Henry Bessemer Street, ZI Acti-Est, CS 10084, 85003 La Roche Sur Yon, and including a copy of their signed identity document.