At Sepro Group, we specialize in delivering engineered, configurable automation solutions tailored to the unique needs of injection molders worldwide. What sets us apart is our complete in-house development of all core technologies — from robotic mechanics to proprietary software and automation integration. This ensures seamless performance, adaptability, and long-term reliability. With over 40,000 injection molding machines equiped globally, Sepro has become a trusted partner in advancing productivity and efficiency through smart automation.

DISCOVER HOW YOUR ROBOT CAN PERFORM MULTIPLE TASKS RIGHT AT THE FOOT OF YOUR INJECTION MOLDING MACHINE OR FURTHER DOWNSTREAM.

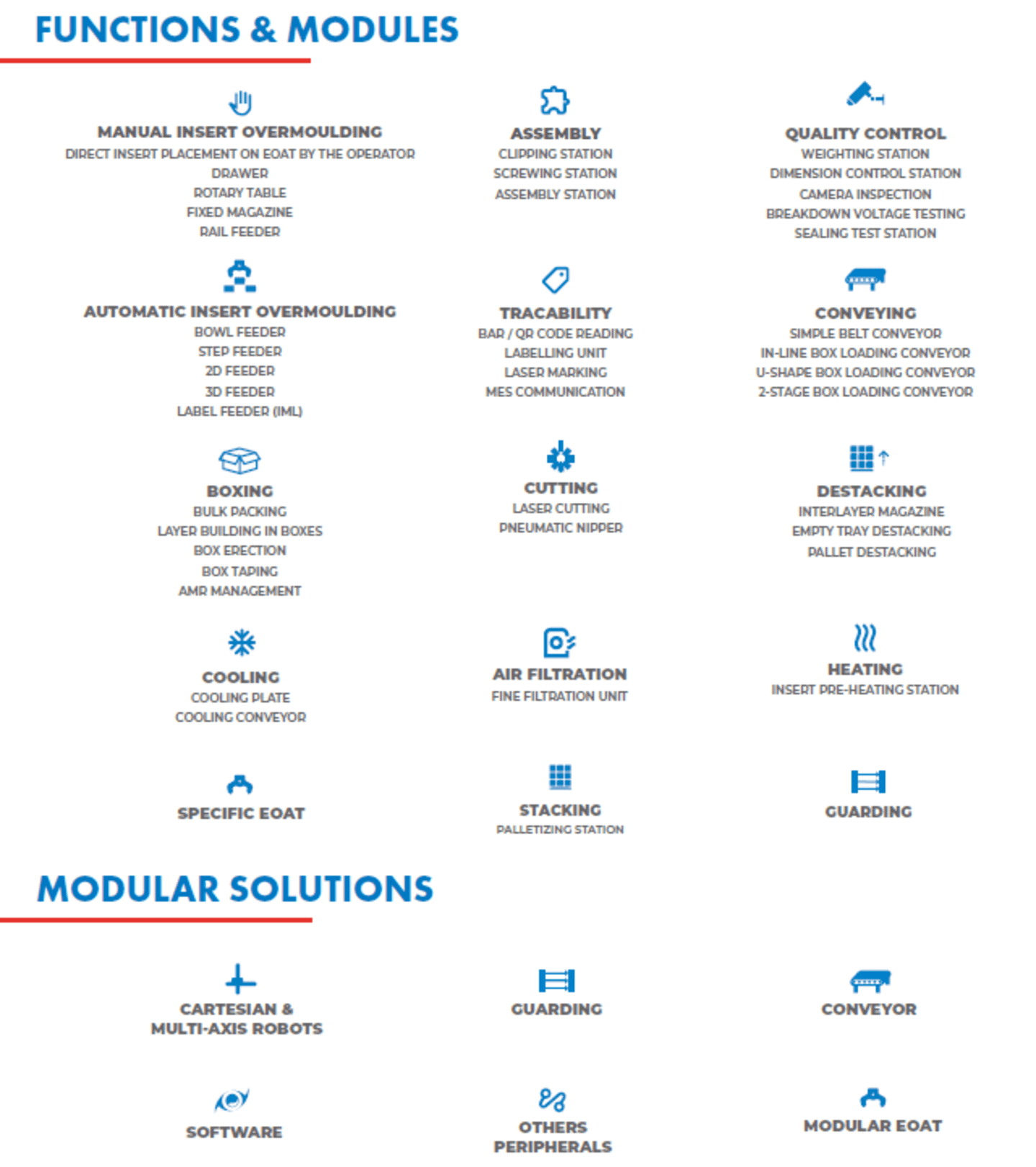

Automating your injection molding operations reduces low-value tasks, enhances part quality, and ensures consistent production. Our modular, versatile robots are designed to automate part take-out from both new and existing machines. They integrate effortlessly with custom automation modules and downstream peripherals for operations such as:

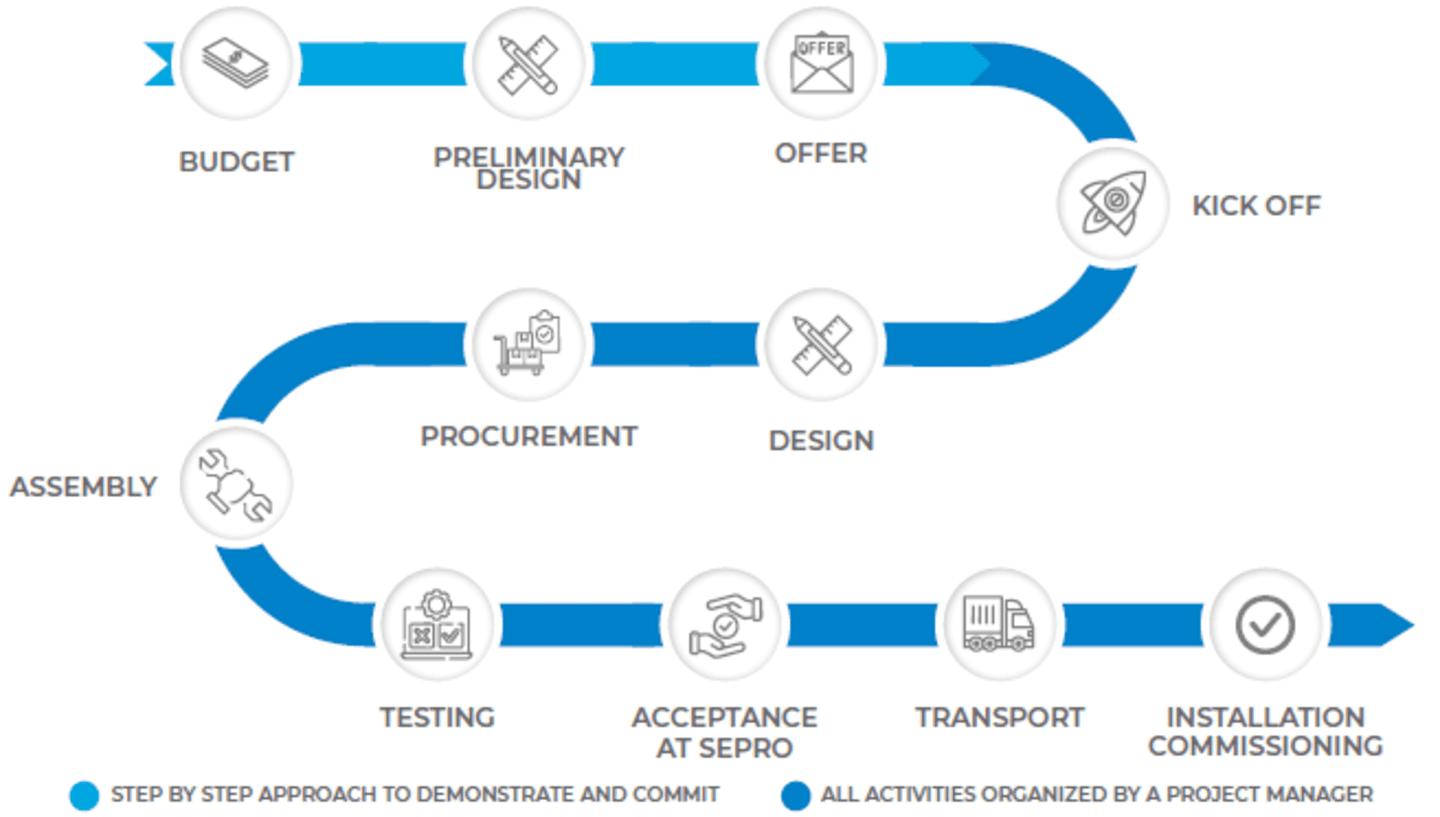

A professional automation process

As a robot manufacturer, software developer, and systems integrator, Sepro collaborates with a network of trusted technology partners. From IMM control to 6-axis integration, vision systems,

and sorting solutions — all components are seamlessly unified within our automation cells. Every Sepro solution is powered by our native Visual controller and enhanced by a dedicated Sepro PLC dashboard, simplifying supervision and maintenance. Our expert engineering teams are committed to supporting you at every stage — from defining your needs to designing and implementing a solution that improves your overall quality and productivity.