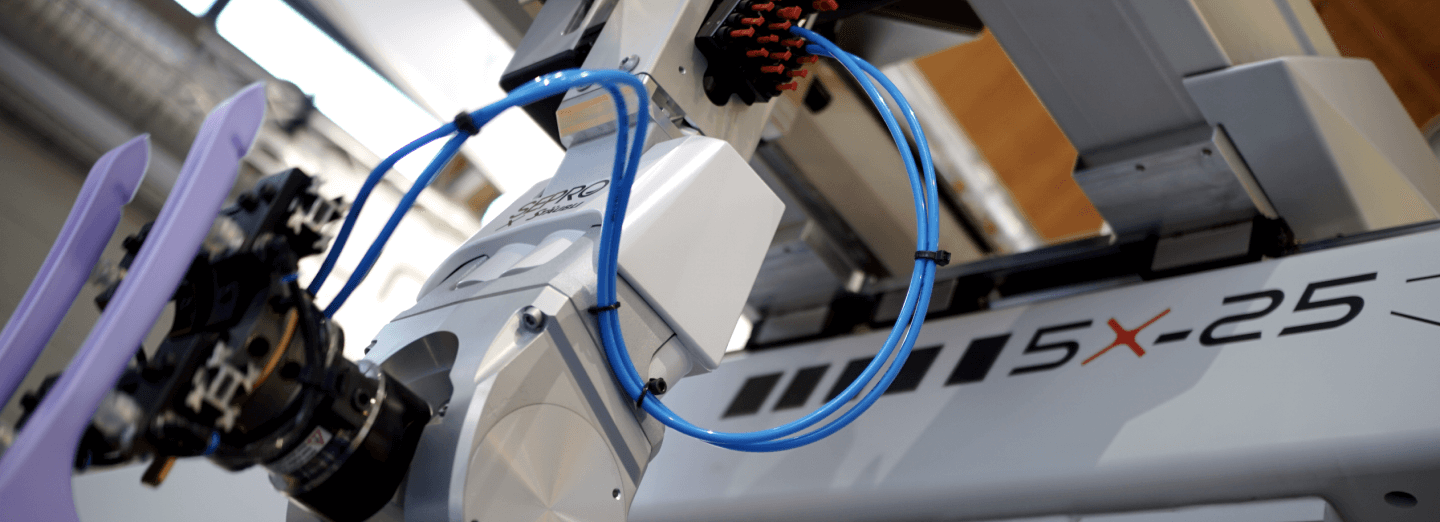

Sepro Group offers courses adapted to your needs on different generations of mechanical and electronic robots. We provide training in your working language, in our centers or in your workshops. All Sepro’s robotics trainers have extensive field experience in France and internationally and are trained in professional training. Our courses are provided with a maximum of 3 persons for 1 robot, and alternate 50% theory and 50% practice to ensure the best learning conditions.

We offer courses throughout the world based on 3 main themes:

- Using a robot in production

- Creating and optimizing cycles

- Robot maintenance

The standard courses, can be adapted according to your needs, in a Sepro’s training center, near your location, or on your production site, anywhere in the world. For more information, please contact us, we will study your needs.

Training catalog