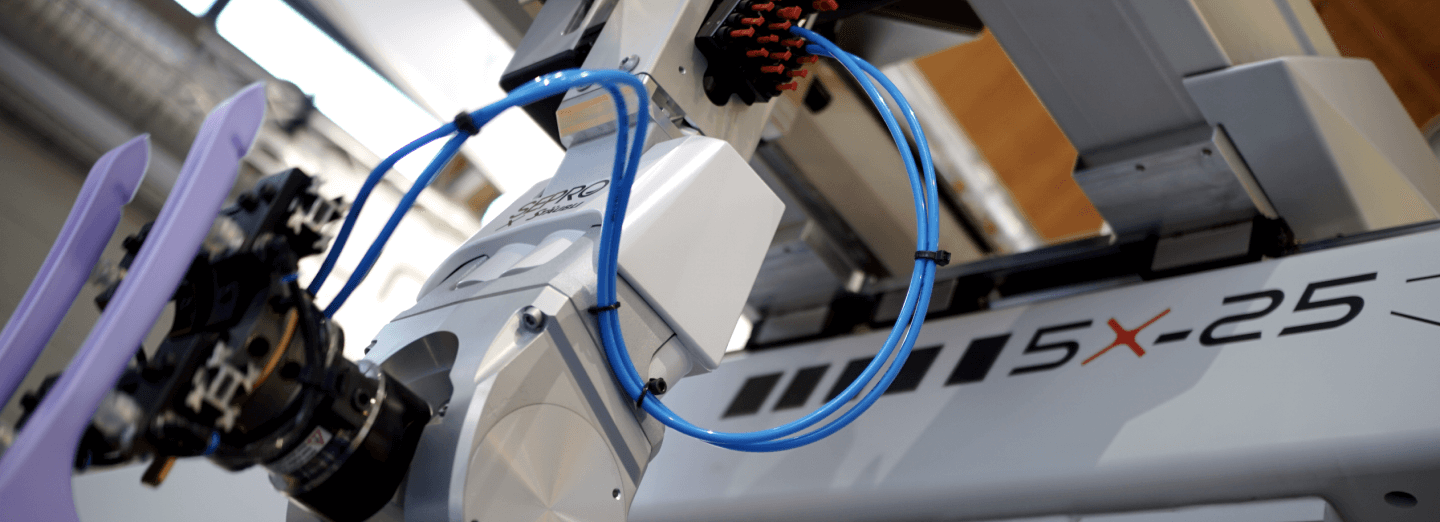

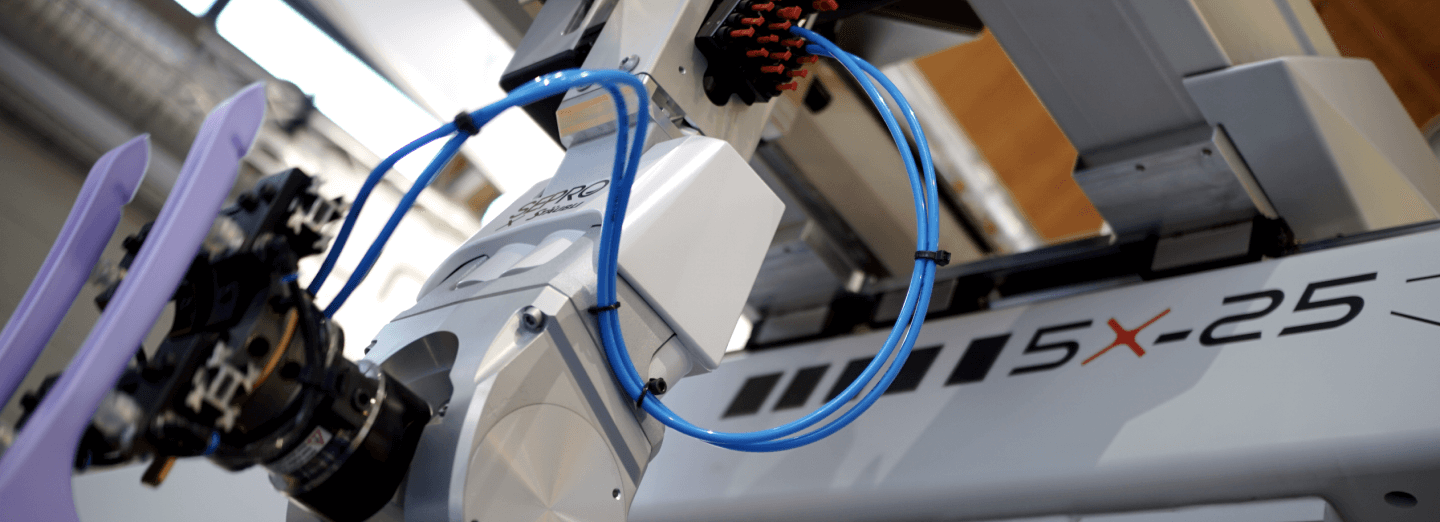

CCA - Creating production cycles

Next sessions

On request

37 Waterside Barns, Lodge Farm Centre, Castlethorpe Business, Milton Keynes MK19 7ES

All of our courses are based on alternating between the transfer of know-how and good practice, with concrete exercises and real-life situations. All trainees will be given a folder containing the documents, exercises and corrections of the practical work done during the course

Cycle

Exploit

Control system

Touch 2

Length

1 whole day or 2 half days.

Audience

Operators

Adjusters

Maintenance Technicians

Prerequisites

None.

Number of people

3 to 8 persons max

Registration

Open to everybody

Completion of training accompanied by official documentation

Attendance sheet provided by Sepro

Touch 2

Visual 2 / Touch 2 / Visual 3

Provide instruction on the fundamentals of robot operation