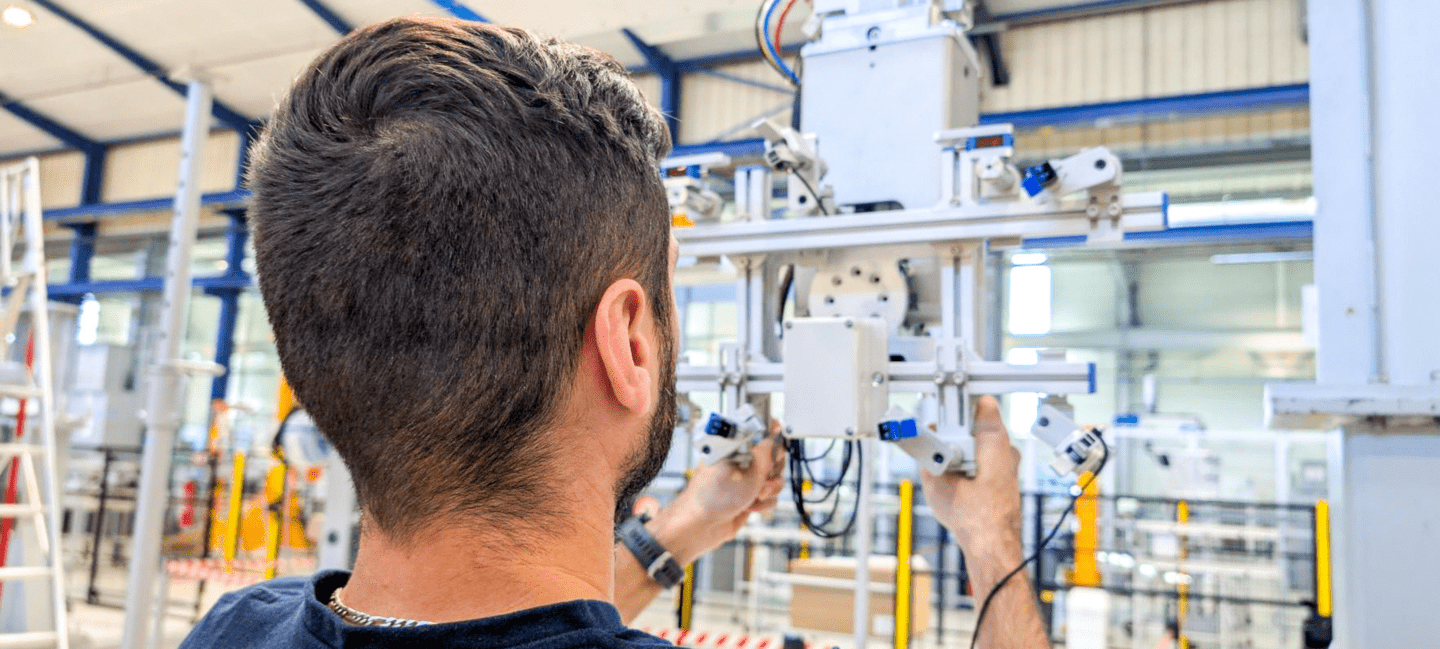

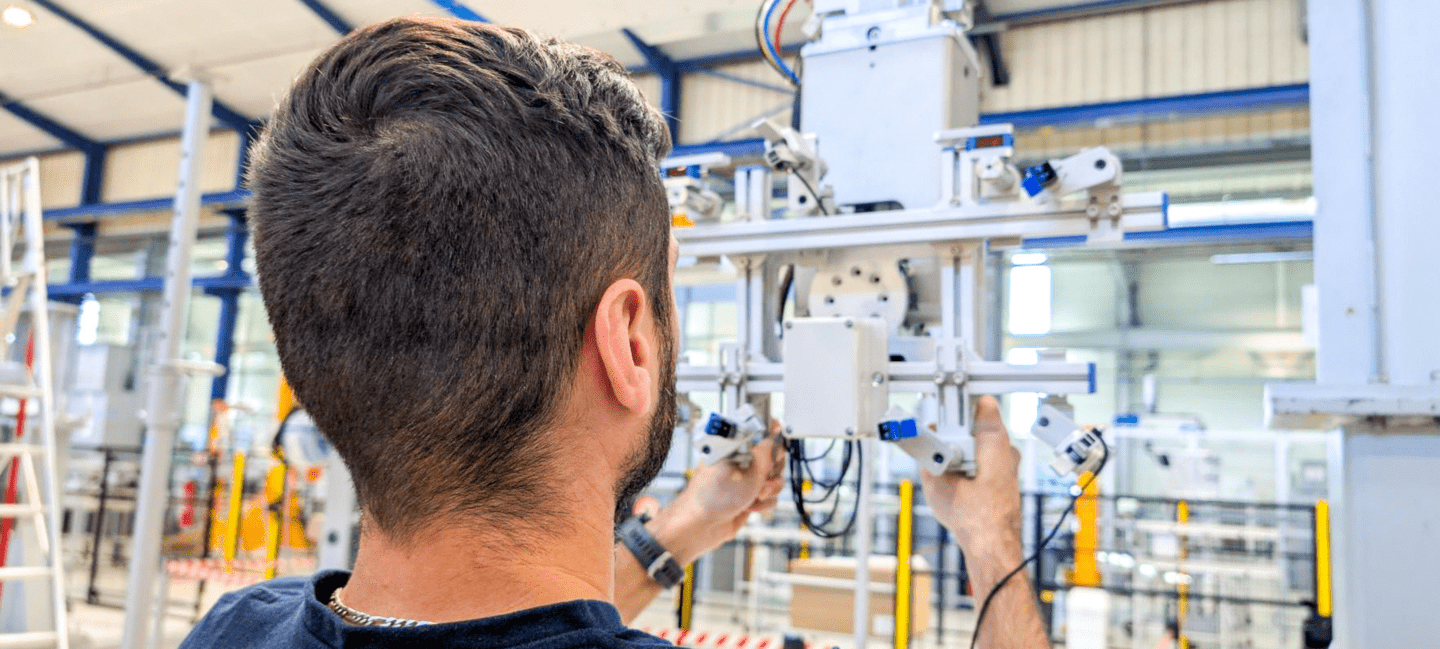

End of arm tooling

Engineered EOAT solution to optimize your cycle time and lifespan of your robot.

Engineered EOAT solution to optimize your cycle time and lifespan of your robot.

Your end of arm tooling is an important component for your production to ensure the good take-out of the part from the mold and optimize the cycle time of your application. The design will vary depending on the type of mold, complexity of the part or the type of post-processing application you are looking for.

A good engineered EOAT will have an impact on your cycle time and on the wear of the robot. A dedicated engineer will advise you between component or fully engineered solutions and will accompany you throughout the entire EOAT design process., from kit componants simple modular solutions to fully engineered solutions adapted to your operations.

A modular end of arm tooling concept engineered for your downstream operations and customized depending on the part, mold and robot specificatons. All modular components are compatible with your standard and current supplier components (grippers, simple fingers, vacuum holders, vacuum suckers, etc.) and can be fitted on a wide range of aluminium profile structures and is compatible with standard components.

This offer is tailor-made for complex process management around the molding cell. Depending on the part or insert, we study and manufacture specific EOATs from rigid compact solutions that are specially designed to your part requirements. Ours EOATs guarantee accuracy, repeatability and flexibility.