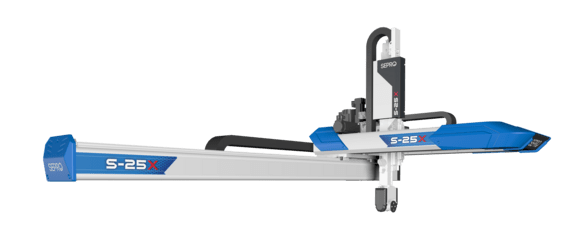

S-Line X

Sepro Group has completed a redesign of its premium robots sized for plastic injection-molding machines with up to 1000 tons of clamping force. Three new S-Line robot models have been designed to serve molding machines from 100 to 1000 tons of clamping force, with three modular options:

- a basic 3-axis servo-driven configuration

- with additional servo wrist rotations for a total of 5 axes of CNC motion

- or in special application-specific configurations such as a medical version adapted for cleanroom environments

Presentation

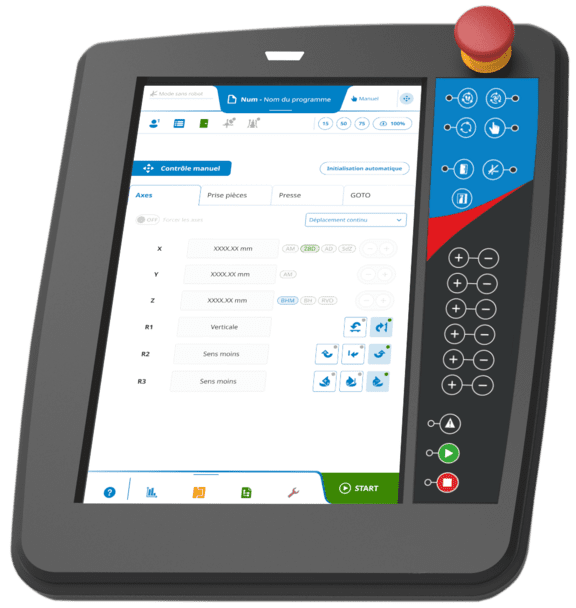

- New controller Visual 4

- 200mm extra demoulfing stroke

- 15% faster than the last generation

- 20% increased payload capacity and 40% in a heavy load configuration

- New modern design

- More rigidity and precision

- LED status indicators on mobile

Control systems

Specifications

Applications

You may also be interested in:

Contact our sales team

All fields are required

How can we help you?

The information collected by SEPRO ROBOTIQUE is processed electronically in order to set up commercial relations between you and SEPRO ROBOTIQUE's Sales Department. Data points collected via this form are required except those marked as optional. Data recipient is SEPRO ROBOTIQUE's Sales Department, the data controller. Your data will be kept for the time necessary to process your requests. Pursuant to the French Data Protection Act of 6 January 1978, as amended, and the GDPR, you have the right to access, query, limit, transfer, modify, correct, and erase your personal data. You may also object at any time to the processing of your personal data. You can exercise these rights by sending us an e-mail to the following address: dataprotection@sepro-group.com or by writing to SEPRO ROBOTIQUE SAS, Henry Bessemer Street, ZI Acti-Est, CS 10084, 85003 La Roche Sur Yon, and including a copy of their signed identity document.