Smart Automation Systems

When Sepro robots are paired with customized, multifunctional end-of-arm tooling, insert feeders, and inspection, assembly and packaging systems, the molding operation immediately becomes more efficient and productive. It becomes possible to deliver components to customers in a more finished form. This moves secondary manufacturing operations out the customer’s plant (reducing their costs and increasing efficiency) and into the molder’s plant, where they increase profitability. Specific capabilities that can be built into automation cells include:

- Part Control… vision; presence/absence of components; electrical continuity

- Part handling… shuttle tables; vertical stackers, conveyers

- Traceability… marking; labeling; separation by cavity

- Assembly… closing; clipping; screwing; gluing; welding

- Cutting… gate vestige removal; flash removal; routing.

Smart Automation at Fakuma 2023

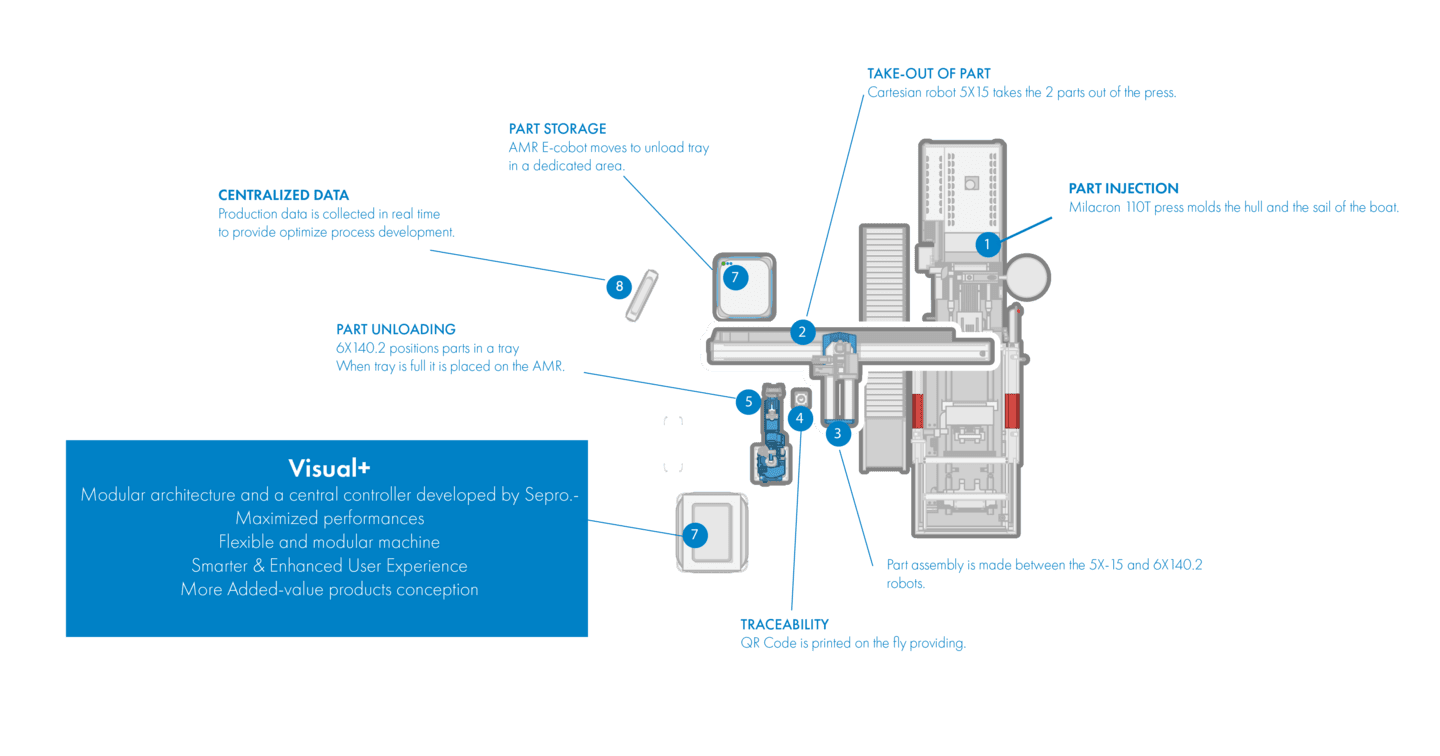

Sepro will be demonstrating the potential power of Smart Automation Systems at Fakuma 2023 being held in Friedrichshafen October 17 – 21. This complex production cell is built around an operating 110-ton Milacron IMM producing toy sailboat components. The molding machine is supported by a Sepro 5X-15 Cartesian robot with servo-driven wrist, and a 6X-140.2 articulated-arm robot and a range of peripheral equipment. The fully automated production process follows this sequence:

- The 5X-15 removes the two components (boat hull and sail) from the mold. Successful gripping is confirmed by a vacuum switch.

- The 5X robot allows the 6X unit to grip the boat hull, while maintaining control of the sail, and the two robots work together to assemble the sail to the hull in mid-air.

- The 6X then regrips the boat, which the 5X has been holding by the sail, and moves it, without stopping, past an inkjet printer.

- The QR code printed on the hull connects to data from the IMM related to the production for that particular boat, which is stored on a cloud server.

- Next, the 6X robot presents the boat for quality assessment by two pneumatic probes. Measurement data is stored on the server, and the boat is placed on a handling tray.

- Once the tray is full, the 6X pushes it onto a conveyor which transfers it out of the guarded molding cell.

- Throughout this sequence of operations, the availability and stack height of empty trays is monitored. A warning is issued automatically to operators when trays need to be restocked or moved.

All the operations and production data are available through Sepro’s Industrial Robot Dashboard which is designed to empower manufacturers with the data and insights needed to help a company excel in productivity, efficiency, and sustainability.

Also at Fakuma, the Robot Dashboard will be used to capture and present operational data on all Sepro robots at the fair… not only those operating on the Sepro stand, but at least six other robots operating on the stands of various injection molding manufacturers.

The fully automated production process follows this sequence:

- REMOVAL FROM IMM -- The 5X-15 removes the two components (boat hull and sail) from the mold. Successful gripping is confirmed by a vacuum switch.

- ASSEMBLY -- The 5X robot allows the 6X unit to grip the boat hull, while maintaining control of the sail, and the two robots, together in tracking synchronization, assemble the sail to the hull in mid-air.

- PRINTING -- The 6X then regrips the boat, which the 5X has been holding by the sail, and moves it, without stopping, past an inkjet printer that marks the boat with a unique QR code.

- TRACEABILITY -- The QR code printed on the hull connects to data related to the production for that particular boat, which is stored on a cloud server.

- QUALITY CHECK -- Next, the 6X robot presents the boat for quality assessment by two pneumatic probes. Measurement data is stored on the cloud server, and the boat is placed on a handling tray.

- LOADING -- Once the tray is full, the 6X pushes it onto an autonomous mobile robot (AMR). The tray’s presence is confirmed by sensors and scales.

- DISTRIBUTION -- The AMR passes through a port in the cell guarding and, using navigation programming, begins to move around the tradeshow booth, distributing boats to visitors on the stand.

- DASHBOARD: Data is collected from all the equipment operating in the cell and displayed in a dashboard proving key indicators for OEE, maintenance of the overall process and also a detailed view per equipment.