Visual Dashboard: Monitor your Production

Smart Data by Sepro Group

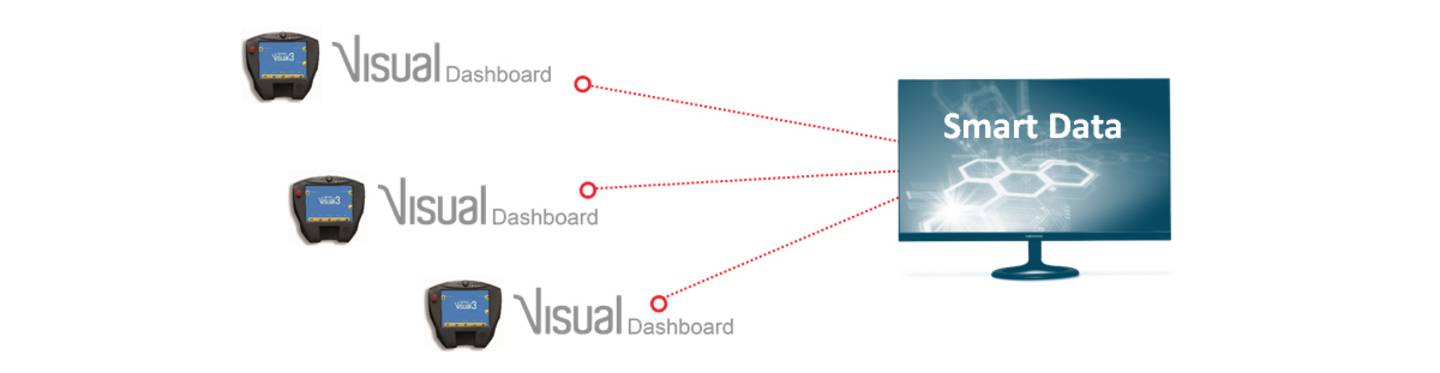

Visual Dashboard is a ‘smart data’ solution that harnesses the power of Sepro’s Visual robot control to collect real-time production data from an IMM served by a Sepro robot. Data include cycle times, mold-open times, and production and quality rates essential to calculating Overall Equipment Effectiveness (OEE). The data collected on several cells can be gathered on an existing MES or integrated on a dedicated platform.

This system can aggregate data even from older IMMs and from machines from different manufacturers.

Sepro robots are already smart sensors. They can collect and compile data

From these, it is easy to calculate:

The data collected by the robot can now be displayed various ways:

Specially developed by Sepro for injection molding machines, the Visual control system makes it easier to use and program your robot.

The Visual 3 control system is adapted for complex applications where several peripherals must be managed and it may include more than two 16I/16O boards.

For more complex applications, Visual 2 controls the different peripheral equipment: conveyors, even complex ones, for palletizing parts and distributing interleaves, insert molding or even a sprue cutter station.

Customer Service is at the heart of our everyday business. We are a designer and manufacturer of robots and leader in our business, and above all we are a company at your Service.

A range of contracts to meet your specific needs from priority phone support to full maintenance.